Tel: 0086 21 5603 2171

Fax: 0086 21 3325 0914

Email: sales@walnutshellpowder.com

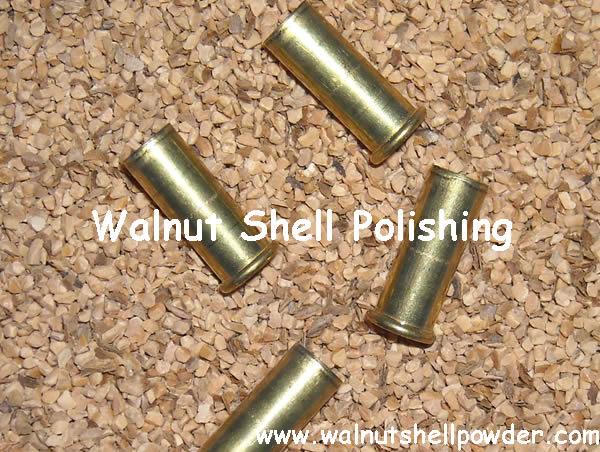

Walnut Shell Polishing

WALNUT SHELL POLISHING MEDIA

Walnut shell polishing media is walnut shell crushed or ground to a specified particle size. The particle size is designed for cleaning cartridge cases in a rotary or vibratory tumbler for reloading, which is an environmentally friendly product that can be reused. The 12/24 walnut shell polishing media is ground to various sizes from coarse to extra fine depending the applications, allowing for a fine degree of control over the desired finish. Walnut shell is used in many polishing and/or deburring applications. Walnut shell media is used for polishing or cleaning fine metals, alloys, mechanical parts, shell cartridges, eye glass lens, rocks, stones, coral, ivory, beans, and seeds. Walnut shell is used as an polishing media similar to sand for polishing or deburring but without the negativities associated with other abrasive materials. Because walnut shell polishing is a gentle, non-corrosive environmentally friendly method of removing burrs, splinter, rusts, wets, edges and corners, without scratching, etching, pitting the substrate material/underlying surface or marring cleaned areas. When used as a polishing media, walnut shell granules are extremely durable, angular and multi-faceted, yet is considered a soft polishing media. Walnut shell polishing media is an excellent replacement for sand (free silica) to avoid inhalation health concerns.

Like other soft media, walnut shell cleans and removes matter from surfaces without damaging underlying material.

Suggested mesh sizes are 4/6, 6/10, 8/12, 12/20, 14/30, 18/40, 35/60, 40/100, 60/200, #100, #200

WALNUT SHELL CLEANING MEDIA

-Premium soft polishing available in English walnut shell grits

-Environmentally friendly, natural, non-toxic; causes no health or environmental hazards

-Long-lasting, re-usable and biodegradable

-Reduces cycle time of finishing operations; preserves microfinishes

-Replaces sand and silica polishing media to avoid problem of silicosis

-Does not produce dust, safe for indoor use

-Angular and multi-faceted, not require flammable solvents

-Polished surfaces require no drying time

-Cleans precisely without a change in dimensions

-Cleaned parts require no additional machining

-The cycle time of finishing operations is drastically reduced

-Fulfills government cleaning requirements.

-The media can be re-used infinitely, cost effective

TECHNICAL DATA MSDS . TDS

|

APPLICATIONS |

Gems Polishing, Jewelry Polishing, Mechanical Parts Deflashing |

|

Mechanical Parts Deburring, Electronics Drying, Mechanical Parts Polishing |

|

USED ON |

Fine Metals, Alloys, Mechanical Parts, Shell Cartridges, Eye Glass Lens, Rocks, Stones, |

|

Coral, Ivory, Beans, Seeds, Jewelry, Molds, Watch, Electronics Brass, Aluminium, Gems |

|

INDUSTRIES |

Electronics, Mechanical Milling, Mechanical Deburring, Mechanical Deflashing |

|

Brass, Aluminium, Gems & Jewelry Polishing, Molds Polishing, Alloys |

|

WALNUT SHELL GRIT |

4/6 6/10 8/12 12/20 18/40 35/60 40/100 60/200 |

|

WALNUT SHELL FLOUR |

#100 #200 |

|

PACKAGING |

20Kgs, 25Kgs, 50Lbs Woven Plastic Bags, Paper Bags |

WALNUT SHELL POLISHING APPLICATIONS

-Ground walnut shell polishing media for rusts removal

-Crushed walnut shell grit for deflashing, deburring & finishing operations

-Deflashing parts in electronics industries

-Deburring in plastics and aluminum & zinc die casting industries

-Excellent media for wheel polishing, air polishin and tumbling operations

-Polishing and cleaning of fine metals, glass, fiberglass, plastic, stone and alloys

-Jewelry, gems and watch polishing